What Is API Bentonite?

API Bentonite refers to a specific grade of bentonite clay that meets the performance and quality standards defined by the American Petroleum Institute. It is typically composed of sodium montmorillonite, a type of clay mineral known for its exceptional swelling and absorptive properties. API Bentonite must pass a series of tests related to fluid loss, viscosity, and yield to qualify under API specifications. These standards ensure consistency and effectiveness in demanding drilling environments. Unlike raw bentonite, API Bentonite undergoes processing and purification to enhance its characteristics, making it suitable for high-performance industrial applications, especially in drilling mud formulations.

Discover how What Is API Bentonite enhances Bentonite Clay Drilling Mud performance.

API Bentonite

API Bentonite is a premium grade of bentonite clay that adheres to the strict standards established by the American Petroleum Institute (API). This specialized clay is an essential material in the oil and gas drilling industry, particularly in the formulation of drilling fluids. API Bentonite is prized for its high swelling capacity, viscosity-building properties, and ability to form suspensions that can withstand high-pressure and high-temperature environments. Its performance characteristics help improve drilling efficiency by stabilizing boreholes, lubricating drill bits, and carrying drill cuttings to the surface. As global demand for energy resources grows, API Bentonite remains a critical resource for upstream drilling operations.

Types of API Bentonite

There are different types of API Bentonite based on their origin, processing, and sodium content:

- Sodium-Based API Bentonite: This is the most commonly used type due to its superior swelling and gel-forming characteristics. It is preferred in drilling applications where high viscosity and yield are needed.

- Calcium-Based API Bentonite: Though naturally less effective than sodium bentonite, calcium bentonite can be chemically treated (activated) to enhance its performance and meet API specifications.

- Activated API Bentonite: Produced by treating natural calcium bentonite with sodium compounds to improve its swelling and viscosity, making it conform to API standards.

Each type has its specific use depending on the project requirements and environmental conditions.

Composition of API Bentonite

API Bentonite is primarily composed of montmorillonite, a smectite clay mineral known for its layered structure and water-absorbing capabilities. A typical composition includes:

- Montmorillonite: 60%–90%

- Quartz: 5%–20%

- Feldspar: 5%–10%

- Other Trace Minerals: Includes calcite, gypsum, and mica

The physical and chemical properties that make API Bentonite effective in drilling fluids include:

- High Swelling Capacity: Enables it to absorb large amounts of water

- Plasticity: Allows easy manipulation and mixing

- Cation Exchange Capacity (CEC): Facilitates ionic interactions in drilling fluids

- Low Filtrate Loss: Helps reduce fluid loss into porous formations

Benefits of API Bentonite

API Bentonite offers a wide range of benefits in drilling and industrial applications:

- Enhanced Borehole Stability: Forms a filter cake that supports borehole walls and prevents collapse

- Improved Lubrication: Reduces friction between the drill bit and borehole walls

- Efficient Cuttings Suspension: Keeps drilling cuttings suspended and allows easy removal from the well

- Controlled Fluid Loss: Minimizes the loss of drilling fluids into the formation

- Environmentally Safe: Naturally occurring and generally non-toxic

These benefits make API Bentonite an essential material in the oil and gas sector, water well drilling, and horizontal directional drilling (HDD).

Explore the natural properties and wide-ranging uses of bentonite in What is Bentonite clay.

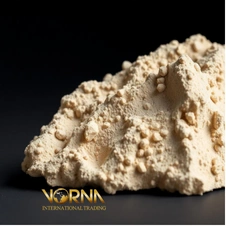

Key Properties of API Bentonite

API Bentonite is defined by several important physical and chemical properties:

- High swelling index: Capable of absorbing many times its weight in water.

- Viscosity control: Builds desired gel strength in drilling fluids.

- Low fluid loss: Limits water loss to the formation, maintaining borehole stability.

- Thixotropy: Forms a gel when static, which helps suspend cuttings.

- Plasticity: Allows for easy mixing and dispersion in water. These properties make API Bentonite a reliable and efficient additive in the formulation of drilling fluids, especially in horizontal and deep drilling scenarios.

Testing Standards for API Bentonite

To be classified as API Bentonite, the product must pass standardized tests developed by the American Petroleum Institute. These include:

- Yield: Typically a minimum of 85 barrels per ton.

- Viscosity: Measured in centipoise using a Marsh funnel.

- Filtration control: Fluid loss should be less than 15 ml in 30 minutes.

- Gel strength: Ability to form a gel under static conditions.

- Sand content: Less than 2% by volume. These tests are conducted in controlled laboratory environments and ensure that API Bentonite delivers consistent and dependable performance in drilling operations.

Industrial Applications of API Bentonite

Although API Bentonite is primarily used in the oil and gas industry, its unique characteristics make it valuable in other sectors as well. In geothermal drilling, it helps maintain borehole stability and manage formation pressures. It’s also used in environmental and geotechnical drilling for its sealing and stabilizing capabilities. In tunneling and microtunneling projects, API-grade bentonite can form slurry walls and support excavations. Additionally, some manufacturers may use API Bentonite in certain chemical processing or filtration systems where high-purity, swelling clays are required. However, its main application remains in the creation of reliable and high-performance drilling muds.

API Bentonite in Drilling Mud

In oil and gas exploration, drilling mud (or drilling fluid) is used to lubricate the drill bit, stabilize the borehole, and carry cuttings to the surface. API Bentonite is a key ingredient in water-based drilling muds due to its superior viscosity-building properties. When hydrated with water, it forms a thick, gelatinous fluid that can suspend solid particles and maintain borehole integrity. It also plays a vital role in cooling the drill bit and preventing formation damage. The API specification ensures that the bentonite used in drilling mud can perform under a wide range of geological conditions, contributing to the success and safety of drilling operations.

What Is API Bentonite serves industrial applications, but bentonite is also essential in food industries. In What is Bentonite winemaking, it helps clarify wine by removing impurities and proteins that affect stability.

API Bentonite vs Other Bentonite Grades

While bentonite is used across various industries, not all bentonite grades meet the rigorous standards required for drilling applications. API Bentonite is specifically processed to achieve a uniform particle size distribution, high purity, and consistent rheological performance. In contrast, other grades like foundry bentonite or civil engineering bentonite may prioritize different characteristics such as binding strength or impermeability. For example, calcium bentonite has a lower swelling capacity than sodium bentonite, making it less suitable for drilling muds. API Bentonite must meet defined criteria for gel strength, fluid loss, and other key parameters, setting it apart from more general-purpose grades.

API Bentonite Suppliers and Pricing

API Bentonite is available globally through specialized suppliers who ensure that their products meet API RP 13A specifications. Pricing for API Bentonite can vary based on several factors including purity, processing method, source location, and bulk volume. Typically, higher-quality bentonite sourced from premium sodium-rich mines commands a higher price due to its superior swelling and viscosity properties. Many suppliers offer API Bentonite in powdered or granulated form, often packaged in bulk bags for industrial use. When sourcing API Bentonite, buyers should verify third-party lab testing results to confirm compliance with API standards, ensuring performance and reliability.

Storing and Handling API Bentonite

Proper storage and handling of API Bentonite are critical to maintaining its quality. The clay should be stored in a dry, moisture-free environment to prevent premature hydration and clumping. Warehouses should be equipped with ventilation and protective coverings to guard against humidity. When handling API Bentonite, dust control measures such as masks and dust extractors are often necessary due to the fine powder form. In field applications, it should be mixed with clean water under controlled conditions to ensure optimal gel development and dispersion. Adhering to best practices in storage and handling ensures consistent product performance during drilling operations.

While What Is API Bentonite is used mainly in drilling, its cosmetic counterpart has a different use. Learn how it’s utilized in skincare through What is Bentonite face mask.