Flash and Fire Point of Bitumen

Flash and Fire Point of Bitumen are critical temperature-related properties that determine how bitumen behaves under heat during handling and application. Bitumen is an essential material widely used in road construction, roofing, and waterproofing, and its performance at elevated temperatures directly affects safety and efficiency. The flash point and fire point of bitumen play a vital role in identifying ignition risks and combustion behavior. In this article, we explore the flash and fire point of bitumen, explaining their significance, testing methods, and importance in construction and industrial applications.

In technical and industrial contexts, the term asphalt is often used interchangeably with bitumen, particularly in regions such as North America. For this reason, expressions like asphalt flash point or flash point of asphalt are commonly found in technical documents and safety guidelines. In practice, these terms refer to the same material behavior, as both asphalt and bitumen exhibit similar flash point characteristics when subjected to high temperatures.

Understanding the flash and fire point of bitumen is essential for ensuring safe handling and storage. For those looking to purchase high-quality bitumen at competitive Bitumen Price, explore our product range tailored to global standards.

What is Flash Point of Bitumen?

The flash point of bitumen refers to the lowest temperature at which bitumen will emit enough vapors to form an ignitable mixture with air. At this temperature, a small flame or spark can cause bitumen vapors to ignite briefly. It’s important to note that the flash point does not mean the bitumen will remain on fire, but it indicates the temperature at which combustion is possible.

In practical terms, the flash point of bitumen typically falls within the range of 230°C to 300°C, depending on the grade, composition, and test method used.

Understanding the flash point of bitumen is critical for safety. Since bitumen is often transported and stored in large quantities at high temperatures, knowing its flash point helps prevent accidental fires and ensure safe handling practices during transportation and storage.

Why is Flash Point of Bitumen Important?

The flash point is an important safety measure in various industries, including construction and roofing, where bitumen is frequently used. In construction, bitumen is applied in roofing systems, roadways, and waterproofing projects, where exposure to heat sources is inevitable.

A low flash point means that the material is more volatile and can ignite easily, posing a higher risk of fire hazards. For this reason, bitumen with a high flash point is preferred for use in these industries to minimize the risk of fire accidents. Additionally, knowing the flash point of bitumen helps manufacturers design appropriate heating and storage systems to maintain safe temperatures during use.

How is the Flash Point of Bitumen Determined?

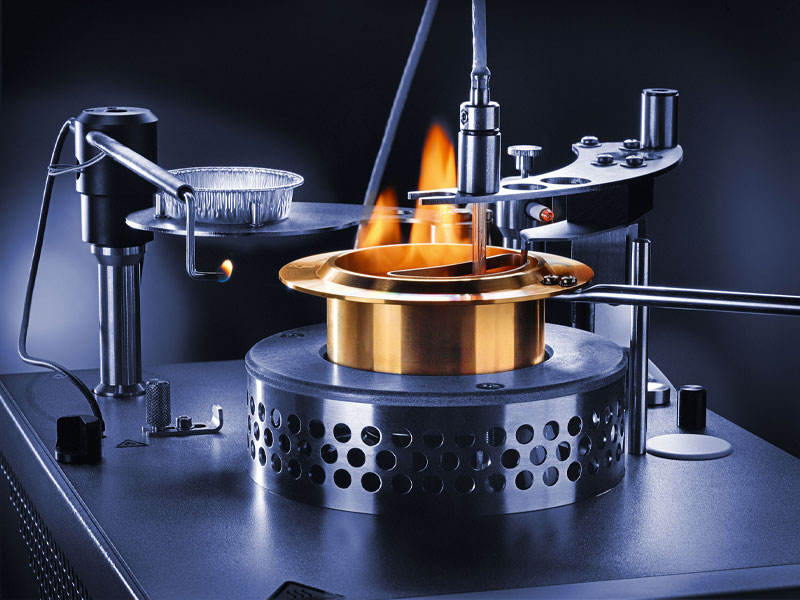

The flash point of bitumen is determined through specific testing procedures that measure the temperature at which the bitumen vapors will ignite. These tests are typically carried out using either the open-cup or closed-cup method.

- Open-Cup Method: In this method, bitumen is heated in an open container, and a flame is introduced at regular intervals to detect whether the vapors will ignite. The lowest temperature at which ignition occurs is recorded as the flash point.

- Closed-Cup Method: This method involves heating the bitumen in a sealed container. A small spark is introduced to test for ignition, and the temperature at which ignition occurs is considered the flash point.

The results of these tests can vary based on factors such as bitumen composition and impurities, so it is important to follow standard testing procedures to ensure accurate results.

What is Fire Point of Bitumen?

The fire point of bitumen is the temperature at which the bitumen vapors will continue to burn after ignition is initiated. In other words, it’s the temperature at which the material will not only catch fire but will continue to burn for a sustained period. The fire point is typically higher than the flash point, as it requires a greater amount of heat to sustain combustion.

While the flash point is a safety concern for ignition, the fire point of bitumen is an indication of the material’s ability to continue burning.

The fire point of bitumen generally falls within the range of 240°C to 330°C, depending on the bitumen grade and testing conditions. It is typically 10°C to 30°C higher than the flash point, representing the temperature at which sustained combustion may occur.

The flash and fire point tests highlight the thermal properties and safety aspects of bitumen, which are crucial in various applications. To fully understand its chemical nature and production process, check out our detailed guide on What is Bitumen?. This will give you a clearer insight into how bitumen behaves under different conditions and why it’s a key material in infrastructure development.

Why is Fire Point of Bitumen Important?

The fire point of bitumen is a key safety parameter that must be considered during its storage and handling. Since bitumen is often heated to high temperatures during manufacturing and application, knowing the fire point helps prevent fire-related accidents.

In industries such as road construction and roofing, where bitumen is commonly used, workers must be aware of the fire point to avoid exposing the material to temperatures that could result in continuous combustion. In these cases, controlling the temperature of bitumen during application is essential to prevent hazardous conditions.

This property is particularly important in fire safety assessments, as it helps in understanding how bitumen will behave in extreme heat conditions.

How is the Fire Point of Bitumen Determined?

The fire point of bitumen is typically determined by subjecting the bitumen to a controlled heating process and then introducing a flame. The temperature at which the bitumen ignites and continues to burn is recorded as the fire point.

Unlike the flash point test, which focuses on ignition, the fire point test examines whether the material will continue to burn after ignition. This test is often done using an open-cup method, where bitumen is heated, and the flame is introduced periodically to assess its behavior under sustained heat.

The Difference Between Flash Point and Fire Point of Bitumen

The flash point and fire point are both important temperature properties of bitumen, but they serve different purposes in safety evaluations. The flash point measures the initial ignition temperature, while the fire point measures the sustained burning temperature.

- Flash Point: The temperature at which bitumen vapors can ignite when exposed to a small flame.

- Fire Point: The temperature at which the bitumen will continue to burn after ignition is initiated.

| Property | Flash Point of Bitumen | Fire Point of Bitumen |

| Typical Temperature Range | ~230°C – 300°C | ~240°C – 330°C |

| Ignition Behavior | Brief ignition of vapors | Sustained combustion |

| Safety Role | Initial fire risk indicator | Continuous fire risk indicator |

| Testing Standard | ASTM D93 | ASTM D92 |

In simple terms, the flash point of bitumen tells you when a material becomes volatile enough to ignite, and the fire point of bitumen tells you how much heat is needed to maintain combustion. Both are critical for assessing the safety and handling of bitumen in different environments.

The Role of Flash and Fire Points in Bitumen Safety

Both the flash point and fire point of bitumen play crucial roles in determining the safety of the material during storage, transport, and application. These temperature properties help industries ensure that bitumen is handled in a manner that minimizes fire risks.

In particular, knowledge of the flash and fire points allows manufacturers and contractors to implement proper safety measures, such as temperature control systems, adequate ventilation, and fire suppression equipment, in environments where bitumen is used.

Flash and Fire Point Testing Standards for Bitumen

Various international standards govern the testing of flash and fire points of bitumen. These standards are designed to ensure that the material is safe to handle and use in construction applications.

For example:

- The ASTM D92 standard is commonly used to test the fire point of bitumen.

- The ASTM D93 standard is used for testing the flash point.

Adhering to these testing standards is essential for ensuring that bitumen is safe for use in high-temperature applications.

Learn more about the differences in behavior and safety between Bitumen vs Asphalt in our in-depth comparison article.