Introduction

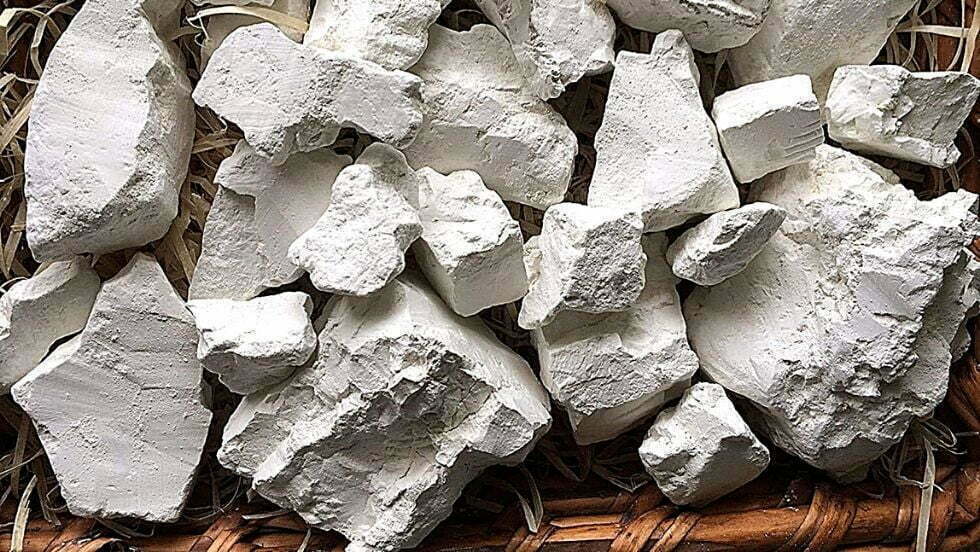

Kaolin, also known as china clay, is a fine, white powder derived from the natural weathering of aluminum silicate minerals such as feldspar and granite. Its remarkable properties have led to its widespread use in various industrial sectors, making it an indispensable resource for countless manufacturing processes.

The Origins of Kaolin

Kaolin deposits can be found in various parts of the world, including the United States, Brazil, China, and the United Kingdom. The formation of kaolin involves the decomposition of rocks and the removal of impurities through natural processes. The resulting mineral is a soft, white clay that can be easily mined and processed.

Kaolin in the Paper Industry

Enhancing Paper Whiteness and Smoothness

One of the primary uses of kaolin is in the paper industry, where it acts as a filler and coating pigment. Kaolin is added to paper pulp to improve its brightness and smoothness, resulting in high-quality paper products.

Improving Ink Absorption

Kaolin’s ability to enhance ink absorption is crucial for the printing industry. When used as a coating in glossy paper, it prevents ink from spreading, ensuring sharp and vibrant print quality.

Read More: Bentonite

Kaolin in Ceramics and Pottery

Enhancing Clay Properties

In ceramics and pottery, kaolin serves as a crucial ingredient, improving clay’s workability, plasticity, and firing characteristics. It also reduces shrinkage during drying and firing.

Aiding in Glaze Formulation

Kaolin is a key component in glaze formulation, providing a smooth and glass-like finish to ceramics and pottery. It also aids in controlling the glaze’s melting temperature.

Kaolin in the Cosmetics and Personal Care Industry

Skin-Friendly Absorbent Properties

The cosmetic industry benefits from kaolin’s absorbent properties, making it an ideal ingredient for face masks, powders, and makeup products. Kaolin gently absorbs excess oils, leaving the skin feeling fresh and rejuvenated.

Dental Applications

Kaolin is used in toothpaste formulations for its mild abrasive properties, helping to remove plaque and stains without harming tooth enamel.

Kaolin in the Rubber Industry

Reinforcement of Rubber Compounds

In the rubber industry, kaolin acts as a reinforcing filler, enhancing the strength and durability of rubber compounds. It also improves resistance to abrasion and wear.

Improved Performance and Durability

Products such as tires, conveyor belts, and automotive components benefit from kaolin’s contribution to improved performance and longevity.

Read More: Wikipedia

Kaolin in Pharmaceuticals

Pharmaceutical Excipients

Kaolin is employed as an excipient in pharmaceutical formulations, aiding in the binding of tablets and the suspension of liquids. It also serves as an adsorbent in antidiarrheal medications.

Drug Formulation and Delivery

Kaolin nanoparticles are being explored for drug delivery systems, offering controlled release and targeted drug delivery, especially in cancer treatment.

Kaolin in Agriculture

Soil Enhancement and Crop Protection

Agriculture benefits from kaolin’s use as a soil conditioner. It improves soil structure, reduces water loss, and acts as a natural defense against pests and diseases in crops.

Animal Health Benefits

Kaolin is used in animal feed to alleviate digestive issues in livestock. It acts as an anti-caking agent and supports overall animal health.

Kaolin in Paints and Coatings

Opacity and Pigment Extender

In the paints and coatings industry, kaolin is used to increase opacity and extend the life of pigments. It also improves paint adhesion to surfaces.

Rust Prevention

Kaolin-based coatings are employed for corrosion protection in various industries, including automotive and marine.

Kaolin in Plastics

Reinforcing Thermoplastics

Kaolin is added to thermoplastics to enhance their mechanical properties, making them stiffer and more impact-resistant.

Flame Retardant Properties

In some plastic applications, kaolin acts as a flame retardant, reducing the risk of fire.

Kaolin in Construction Materials

Concrete Additive

Kaolin improves the workability and durability of concrete, making it an excellent additive for construction materials.

High-Quality Tiles and Ceramics

In the production of tiles and ceramic products, kaolin ensures a smooth finish and vibrant glaze.

Kaolin in the Energy Sector

Fracking Fluids

Kaolin is used in hydraulic fracturing (fracking) fluids to control fluid loss and improve wellbore stability during drilling operations.

Catalysts for Refining

In the energy sector, kaolin-based catalysts are employed in the refining of petroleum products.

Environmental Applications of Kaolin

Wastewater Treatment

Kaolin is utilized in wastewater treatment to remove impurities and clarify water, contributing to environmental sustainability.

Air Pollution Control

In air pollution control, kaolin-based materials are used to capture and remove harmful pollutants from industrial emissions.

The Future of Kaolin: Innovations and Advancements

As industries continue to evolve, kaolin remains at the forefront of innovation. Ongoing research explores new applications and improved processing techniques, ensuring that kaolin will continue to be a vital resource in the years to come.

Read More: Salt

Conclusion

In conclusion, kaolin’s versatility and unique properties have secured its place as a valuable mineral across various industrial sectors. From paper production to pharmaceuticals, cosmetics to construction, and even environmental applications, kaolin continues to play a pivotal role in enhancing product quality and sustainability.