Barite is a mineral that holds significant importance in various industries, from oil drilling to the creation of barium compounds. In this article, we will explore the essential characteristics of Barite, including its hardness, cleavage, properties, density, specific gravity, chemical formula, and chemical composition. Let’s dive into these aspects to better understand the mineral that plays a crucial role in both industrial applications and scientific studies.

What is Mineral Barite?

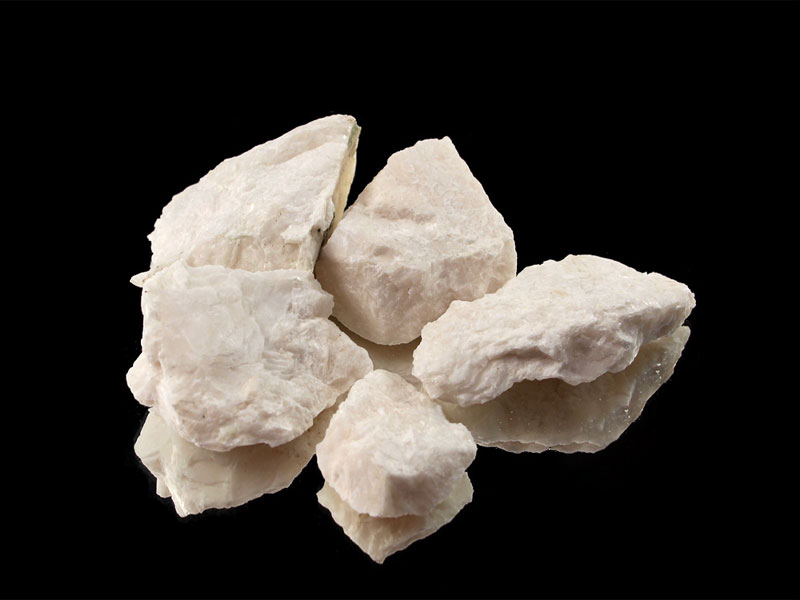

Barite, also known as baryte, is a mineral primarily composed of barium sulfate (BaSO₄). It forms in a variety of environments, including sedimentary rocks and hydrothermal veins. Barite’s most common occurrence is in lead-zinc deposits, and it can also be found in sedimentary deposits as a secondary mineral formed from the alteration of other minerals.

you can read more about other minerlas like What is Kaolin-Pectin for dogs

Introduction to Barite

Barite has a white, gray, or colorless appearance, but it can also exhibit a variety of colors due to impurities. It is widely used in the oil and gas industry, as its dense nature makes it perfect for drilling muds in the process of oil extraction. Apart from this, Barite also finds applications in the production of barium chemicals, paint, rubber, and plastics.

Properties of barite

Transparency of barite

While generally translucent to opaque, some varieties of barite can be transparent. This property is of significance in applications where optical clarity is essential.

Magnetism of barite

Barite is non-magnetic, a property that influences its use in magnetic separation processes in various industries.

Solubility of barite

In contrast to its low solubility in water, barite is soluble in concentrated hydrochloric acid, providing a method for its chemical analysis.

Color and Streak of mineral barite

Barite’s color can range from colorless to shades of blue, brown, or red. Interestingly, its streak, the color left when scratched on a surface, is always white, a feature crucial for identification.

barite Crystal Structure

Barite crystallizes in the orthorhombic system, forming distinctive tabular crystals. This unique crystal structure contributes to its stability and suitability for diverse applications.

read more about : Bitumen Price

Barite Hardness

The hardness of Barite, on the Mohs scale, is 3 to 3.5. This places it in the same range as calcite, meaning it is relatively soft compared to many other minerals. The Mohs scale measures the resistance of a mineral to scratching, with 1 being the softest and 10 being the hardest.

Barite’s moderate hardness makes it susceptible to scratching by harder materials like glass or steel. However, it is strong enough to be useful in various industrial applications, such as in the manufacture of heavy-duty industrial products, where its density is more important than its hardness.

Importance of Quality Control

Ensuring the consistent quality of barite is paramount, especially in industries where its physical properties play a critical role. Quality control measures safeguard against variations that could impact performance.

Barite Cleavage

Barite displays perfect cleavage along the basal plane, which means it can break along smooth, flat surfaces. This cleavage property is a significant factor in its identification. The mineral typically forms tabular or prismatic crystals that easily break along these planes, making it an important characteristic when studying or identifying Barite in the field.

Due to its perfect cleavage, Barite can often break into thin, sheet-like pieces. This property is essential in various applications where uniformity in the shape of the mineral is required, such as in the production of certain chemical compounds.

Barite Properties

Barite has several key properties that make it valuable across a wide range of industries. These properties include its appearance, luster, and unique physical characteristics:

-

Appearance: Barite is most commonly found in white or colorless forms, but it can also be seen in shades of yellow, blue, brown, and red due to impurities.

-

Luster: Barite has a vitreous to pearly luster, which gives it a shiny appearance when light hits its surface. This makes Barite quite visually appealing when used in decorative items.

-

Streak: Barite leaves a white streak when scratched across a piece of unglazed porcelain, which is a crucial feature for identifying this mineral.

-

Brittleness: Given its moderate hardness and perfect cleavage, Barite tends to be brittle, breaking easily into smaller pieces.

These properties are fundamental in identifying Barite in nature and understanding its applications in industry.

read more about other barite : Red barite

Barite Density and Specific Gravity

Barite is known for its remarkable density. The mineral’s density is typically 4.5 g/cm³, making it one of the densest minerals found in nature. This high density is one of the reasons Barite is so useful in the oil and gas industry, particularly in drilling operations. In these applications, Barite is used in drilling fluids to add weight and help control the pressure in the borehole during drilling.

Specific Gravity of Barite:

The specific gravity of Barite is also quite high, typically around 4.3 to 4.6. Specific gravity refers to the ratio of a mineral’s density to the density of water. For Barite, this high specific gravity makes it valuable in processes where weight and density are crucial, such as in the production of cement and as a weighting agent in drilling fluids.

Barite Chemical Formula

Barite’s chemical formula is BaSO₄, meaning it is composed of one barium (Ba) atom, one sulfur (S) atom, and four oxygen (O) atoms. This composition gives Barite its characteristic properties, such as its high density and perfect cleavage. The chemical structure is relatively simple, yet it results in a mineral with a wide range of industrial uses.

The combination of barium and sulfate in Barite also makes it an essential source of barium compounds, which are widely used in various chemical processes and applications.

Barite Chemical Composition

While the chemical formula of Barite is straightforward (BaSO₄), its composition can sometimes include trace elements or impurities that alter its color and properties. These impurities may include elements like calcium, iron, and strontium, which can affect its overall appearance and density. However, the core structure remains largely the same, with barium sulfate as the primary component.

Before delving into its physical properties, let’s briefly touch upon the chemical composition of barite. Its basic structure consists of one barium (Ba) atom bonded to two sulfate (SO4) groups, creating a stable and distinctive compound.

Barite can also occur in different varieties, such as:

-

Celestine (SrSO₄): A mineral similar to Barite, where barium is replaced by strontium.

-

Witherite (BaCO₃): A mineral in which barium is combined with carbonate instead of sulfate.

These variations are less common but still noteworthy in the broader context of Barite’s chemical composition.

Types of Barite

Barite mainly exists in two primary forms: Natural Barite and Synthetic Barite.

-

Natural Barite:

-

Natural Barite is found in nature as a mineral composed of barium sulfate (BaSO₄). It typically forms in sedimentary environments such as limestone deposits or hydrothermal veins.

-

It is the most common type used in various industrial applications. Natural Barite can have impurities that affect its color and density but its core properties remain useful in most cases.

-

-

Synthetic Barite:

-

Synthetic Barite is artificially produced in laboratories or factories. This type is often manufactured by precipitating barium sulfate from a solution of barium chloride and sodium sulfate.

-

Synthetic Barite is sometimes preferred for specific uses because it can be produced with higher purity and controlled particle size, which is important for certain high-precision applications.

-

Barite in the Medical Field

The unique physical properties of barite find application in medical imaging, where its high density enhances the visibility of certain tissues during diagnostic procedures.

Barite and Oil Drilling

In the oil and gas industry, barite’s use as a weighting agent in drilling fluids is indispensable. Its physical properties contribute to the efficiency and success of drilling operations.

Future Prospects

Considering the versatility of barite, its future prospects look promising. Ongoing research and technological advancements may unveil new applications, further increasing its demand.

read more about other mineral products like kaolin clay soap

Applications of Barite

Barite has a wide range of applications in different industries. Some of its most common uses include:

-

Oil and Gas Industry:

-

Barite is extensively used in the oil and gas industry as a weighting agent in drilling fluids. Its high density helps control pressure during drilling operations and prevents blowouts by stabilizing the wellbore.

-

-

Production of Barium Compounds:

-

Barite is an important raw material for the production of various barium compounds, such as barium carbonate and barium hydroxide, which are used in manufacturing glass, ceramics, and electronics.

-

-

Paints and Coatings:

-

Barite is used as a pigment and filler in the production of paints and coatings. Its high density improves the performance of the coating, especially for marine, industrial, and protective paints.

-

-

Rubber and Plastics:

-

Barite is added to rubber and plastics to improve their properties. Its density helps enhance the weight, strength, and durability of these materials.

-

-

Radiation Shielding:

-

Due to its high atomic number, Barite is used in radiation shielding, especially in the medical and nuclear industries, where it helps block gamma radiation.

-

Advantages of Barite

-

High Density:

-

Barite’s high density (around 4.5 g/cm³) makes it invaluable in industries such as oil drilling, where it is used in drilling fluids to control well pressure.

-

-

Chemical Stability:

-

Barite is chemically inert and stable, which makes it resistant to weathering and corrosion. This property ensures its durability when used in various industrial processes.

-

-

Non-toxic:

-

Barite is non-toxic and safe to handle, which makes it suitable for use in products such as paints, rubber, and plastics.

-

-

Wide Range of Applications:

-

Due to its diverse properties, Barite is utilized in multiple industries, from oil drilling to the production of barium chemicals and radiation shielding.

-

Methods of Production

Barite is produced primarily through two methods:

-

Mining and Extraction:

-

Natural Barite is extracted from the earth through traditional mining methods. The ore is typically found in sedimentary deposits or hydrothermal veins. Once extracted, it is crushed and processed to remove impurities and achieve the desired size.

-

-

Synthetic Production:

-

Synthetic Barite is manufactured by chemical precipitation, where barium chloride (BaCl₂) reacts with sodium sulfate (Na₂SO₄) to form barium sulfate (BaSO₄). The process can be controlled to produce Barite with specific particle sizes, which is especially important for applications requiring high purity and consistency.

-

Mining Mineral barite and Extraction

Understanding the physical properties of barite is pivotal in the mining and extraction processes. Efficient extraction methods leverage its specific gravity and hardness, ensuring cost-effective operations.

Barite Market Trends

Examining the current market trends reveals a growing demand for barite, driven by its diverse applications in oil drilling, paints, and medical imaging.

Safety Measures in Barite Handling

Handling barite requires adherence to safety protocols, considering its weight, potential dust hazards, and chemical properties. Implementing proper safety measures is essential in industrial settings.

Conclusion

In conclusion, the physical properties of barite make it a versatile and sought-after mineral in various industries. From its density aiding drilling operations to its application in medical imaging, barite’s unique attributes continue to shape its relevance in the market.