When it comes to drilling in the oil and gas industry, the materials used play a pivotal role in the success of drilling operations. One such material that is indispensable in this field is barite. In this article, we will delve into what barite is and why it is so crucial in drilling. We’ll explore its physical properties, its role in drilling fluids, and its impact on drilling efficiency. Additionally, we’ll discuss the process of mining and producing barite, as well as environmental considerations and alternatives to this essential mineral.

What Is Barite?

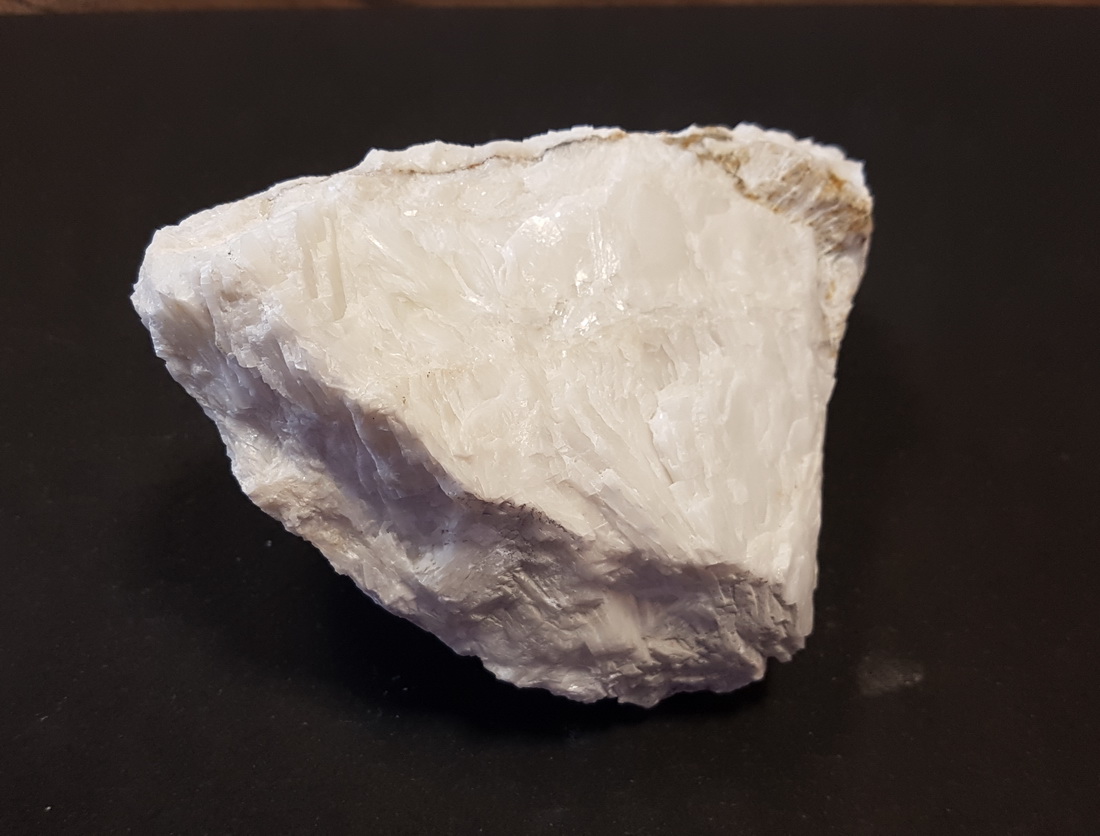

Barite, chemically known as barium sulfate (BaSO4), is a mineral that is often found in nature as a white or colorless crystalline solid. It is abundant and has a high density, making it a valuable resource in various industries, including drilling.

Barite in Drilling: A Brief Overview

Barite’s application in drilling is mainly related to its high specific gravity, which makes it an ideal weighting agent in drilling fluids. Drilling fluids, commonly known as drilling mud, serve several crucial purposes in drilling operations, such as cooling the drill bit, removing cuttings from the borehole, and preventing blowouts.

Barite’s Physical Properties

Barite exhibits some remarkable physical properties that make it suitable for use in drilling. Its high specific gravity, which can range from 4.0 to 4.4, is one of the highest among naturally occurring minerals. This means that a small quantity of barite can significantly increase the density of the drilling mud.

Read More: Kaolin

Importance of Barite in Drilling Fluids

How Barite Enhances Drilling Efficiency

The primary purpose of adding barite to drilling fluids is to increase their density. This enhanced density is essential for controlling formation pressure, preventing well blowouts, and ensuring the stability of the borehole.

The Drilling Fluid Composition

Drilling fluids are a mixture of various components, including water, clay, polymers, and additives. The addition of barite alters the composition by increasing the overall weight of the fluid, which is crucial for achieving the desired drilling outcomes.

Barite’s Role in Mud Weight

One of the key functions of barite in drilling fluids is to control the mud weight. Maintaining the right mud weight is vital to balancing the pressure from the surrounding rocks and preventing uncontrolled fluid migration.

Controlling Formation Pressure

In drilling, it is essential to balance the pressure exerted by the formation being drilled. Barite helps in achieving this balance, thereby preventing formation damage and improving drilling efficiency.

Preventing Well Blowouts

Barite also contributes to well control by preventing well blowouts. Its ability to increase mud weight aids in sealing the wellbore and averting potential disasters.

Read More: Wikipedia

Barite Mining and Production

The extraction of barite is primarily done through mining. Barite is often found in association with minerals like celestine, anglesite, and anhydrite. Once mined, it undergoes various processes, including crushing, milling, and beneficiation, to meet the quality requirements for drilling applications.

Quality Requirements for Drilling Barite

For barite to be used effectively in drilling, it must meet stringent quality standards. Impurities and inadequate processing can compromise the performance of drilling fluids, making the selection of high-quality barite a crucial aspect of drilling operations.

Environmental Considerations

The mining and processing of barite, like many industrial activities, have environmental implications. It is essential for the industry to adopt sustainable practices and minimize the environmental impact of barite production.

Alternatives to Barite in Drilling Fluids

While barite is widely used in drilling, there is ongoing research into alternative materials that can serve the same purpose. These alternatives aim to reduce environmental impact and provide drilling solutions that are more sustainable in the long run.

\Read More: Salt

Conclusion

In conclusion, barite’s role in drilling is indispensable. Its unique physical properties and ability to enhance drilling fluids’ density are vital to the success and safety of drilling operations. The mining and use of barite must be done responsibly to minimize environmental impact. As the industry evolves, research into alternative materials continues, promising a more sustainable future for drilling.