Introduction to White Barite

White barite, a fascinating mineral with numerous industrial applications, has been garnering attention in recent years. In this article, we will delve into the world of white barite, exploring its formation, properties, applications, environmental impact, extraction, and more. So, let’s begin our journey into the realm of this remarkable mineral.

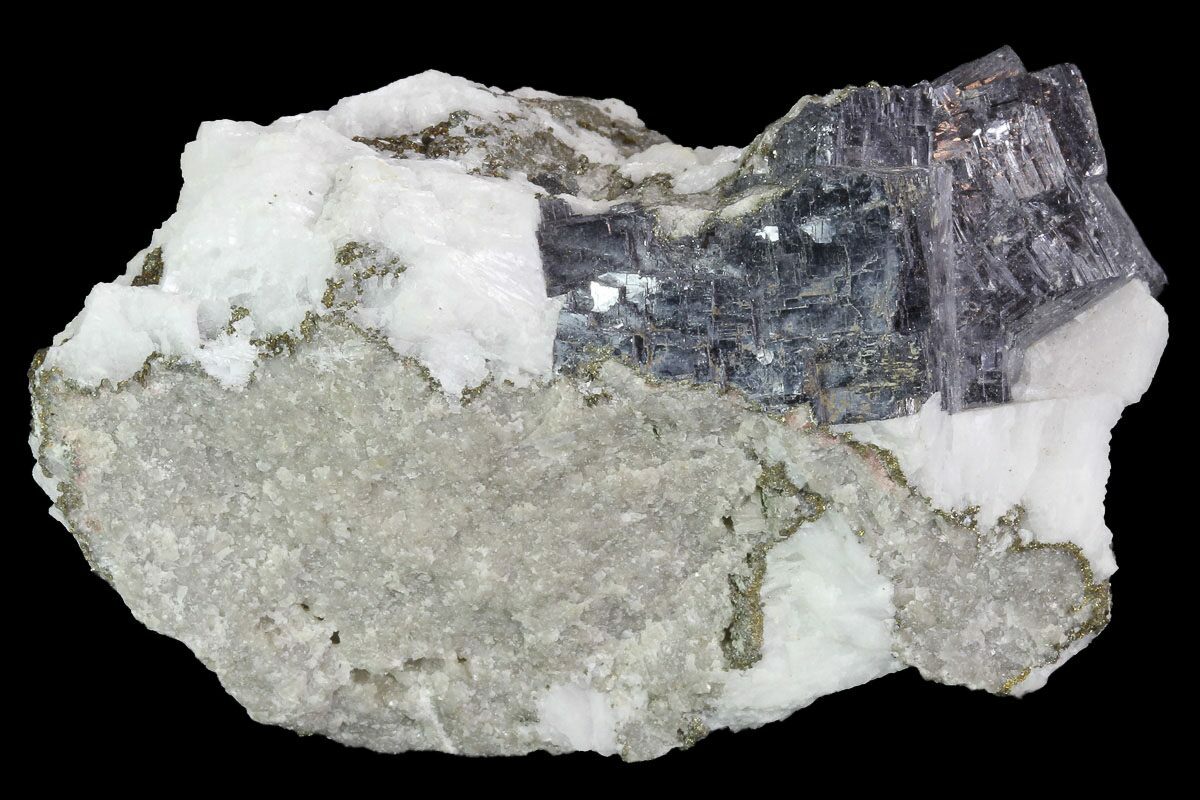

The Formation of White Barite

White barite, scientifically known as barium sulfate, forms when barium ions in the Earth’s crust combine with sulfate ions. The result is the creation of beautiful, white, and opaque crystals. The mineral’s formation usually occurs in hydrothermal veins, sedimentary rocks, or as gangue minerals in metallic ore deposits.

Types and Varieties of White Barite

There are several varieties of white barite, with different crystal structures and chemical compositions. Notable among these are bladed barite, rose barite, and desert rose. Each type has unique characteristics and appearances, making them sought after by collectors and industries alike.

The Properties of White Barite

White barite is renowned for its exceptional density, which is crucial for various applications. It is also non-reactive, non-magnetic, and thermally stable. Its high refractive index makes it valuable in the production of paints and coatings, as well as in the field of radiology.

Read More: Bentonite

Industrial Applications of White Barite

White barite has an array of industrial uses. It is a vital component in the manufacturing of paints, coatings, plastics, and rubber, where it acts as a filler and extender. In the oil and gas industry, it is used as a weighting agent in drilling fluids. Additionally, it finds application in the production of cement, ceramics, and glass.

Environmental Impact

The mining and processing of white barite can have environmental consequences. The excavation process may lead to habitat disruption and the release of heavy metals. Proper environmental regulations are essential to mitigate these impacts and protect natural ecosystems.

Extraction and Processing

White barite is extracted from mines, where it is often found alongside other minerals. The ore is then processed to remove impurities and increase its barium sulfate content. The high-purity white barite is used in the pharmaceutical and medical industries.

Global Distribution

White barite is distributed globally, with significant deposits found in countries such as China, India, the United States, Morocco, and Mexico. The availability of white barite resources varies from region to region, affecting its market dynamics.

Market Trends and Demand

The demand for white barite is influenced by its wide range of applications in various industries. Market trends show a steady increase in consumption due to the growth of construction, oil and gas, and healthcare sectors. This trend is expected to continue in the coming years.

Read More: Wikipedia

Benefits of White Barite

White barite’s low solubility and high density make it indispensable in various industries. Its applications contribute to the production of durable and high-quality materials, enhancing the efficiency of processes in several sectors.

Challenges and Concerns

The mining and processing of white barite present challenges related to environmental impact and worker safety. The industry must address these concerns and adopt sustainable practices to ensure a brighter future.

Alternatives to White Barite

Researchers are continually exploring alternative materials to reduce dependence on white barite. These alternatives aim to maintain or enhance the properties and functions of barite while being more environmentally friendly.

White Barite in the Medical Field

In the medical field, white barite plays a crucial role in X-ray imaging and contrast-enhanced studies. Its high density makes it an ideal contrast agent in radiology, aiding in the diagnosis of various medical conditions.

Read More: Salt

Conclusion

White barite, with its wide-ranging applications and unique properties, is an essential mineral in various industries. Its high density, non-reactive nature, and thermal stability make it a versatile material that enhances the quality of products and processes. However, it is imperative for the industry to address environmental concerns and explore sustainable practices for a more eco-friendly future.