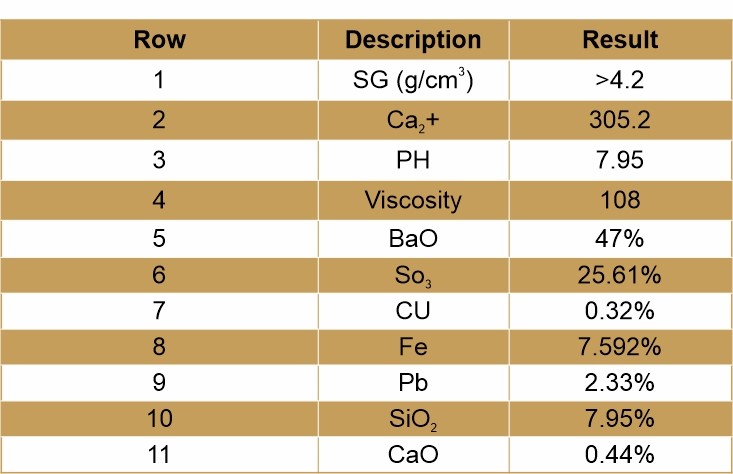

Description

Barite Drilling Mud

Vornaco, as a leading supplier and manufacturer of high-quality barite, provides barite used in drilling mud applications to control the pressure within the wellbore during oil and gas drilling. The dense nature of barite is crucial in balancing the pressure exerted by the underground formations, preventing blowouts. Barite in drilling mud also helps lubricate the drill bit and carry rock cuttings to the surface. It plays an essential role in deepwater and high-pressure drilling projects, ensuring that the wellbore remains stable throughout the drilling process. Vornaco ensures that its barite drilling mud meets international standards for safety and efficiency.

Drilling Barite is crucial for pressure control in drilling. For efficient wellbore stabilization, turn to Bentonite Exporters at Vornaco, offering top-quality bentonite for drilling operations.

Barite Drilling Fluid

Barite drilling fluid is an essential part of the drilling process, helping maintain wellbore pressure and providing lubrication for the drill bit. By incorporating barite, drilling fluid helps to control the pressures exerted by underground formations, preventing dangerous blowouts. Vornaco, known for being a trusted distributor and supplier of barite, ensures that its barite drilling fluid offers superior performance in a variety of drilling environments. The high specific gravity of Vornaco’s barite makes it ideal for balancing the pressure in the wellbore and ensuring the overall efficiency of the drilling process.

Drilling Barite

Drilling barite is a high-density mineral that plays a key role in wellbore pressure control during drilling operations. Vornaco provides drilling barite with high specific gravity, ensuring that the pressure inside the wellbore is managed effectively to prevent blowouts. As a reliable producer of drilling barite, Vornaco ensures that all products meet strict quality standards, providing a reliable solution for safe drilling operations. The high density of drilling barite allows for efficient and smooth drilling, even in challenging conditions, making it a crucial component for the oil and gas industry.

API Barite for Drilling

API Barite for drilling is the high-grade barite that meets the standards set by the American Petroleum Institute (API). Vornaco provides API barite that is specifically designed to meet these strict criteria for use in drilling operations. API barite is essential for maintaining wellbore pressure and ensuring safe drilling practices. By sourcing only the best-quality barite, Vornaco guarantees that its API barite meets all the required specifications for efficient and safe drilling operations, providing the performance needed in high-pressure and deepwater drilling environments.

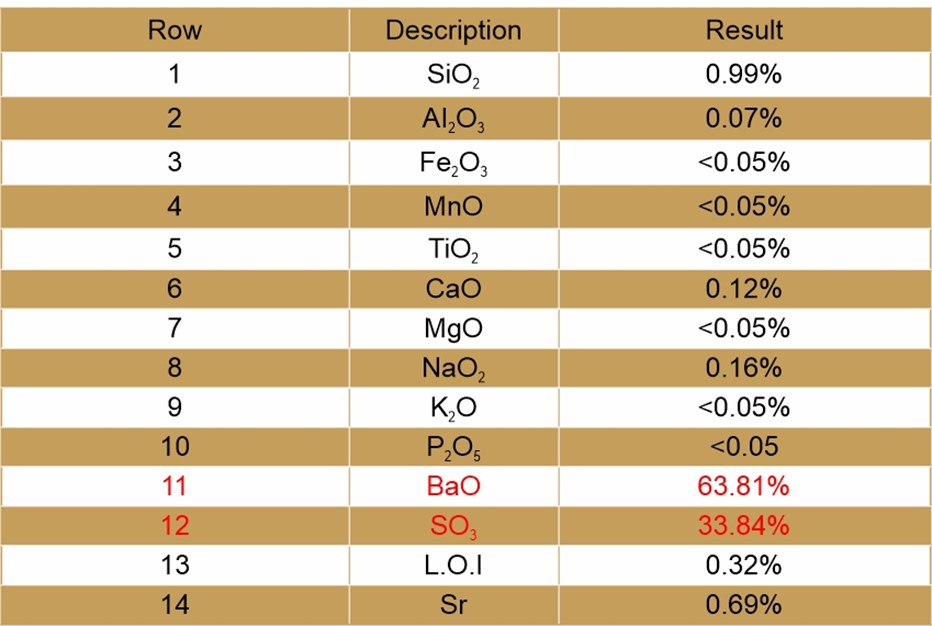

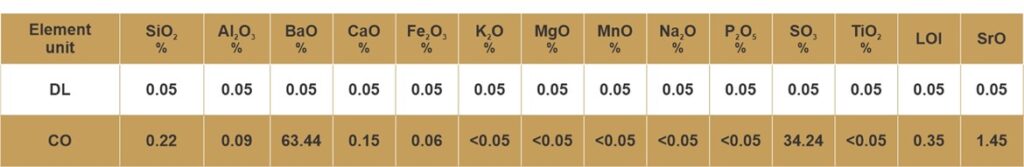

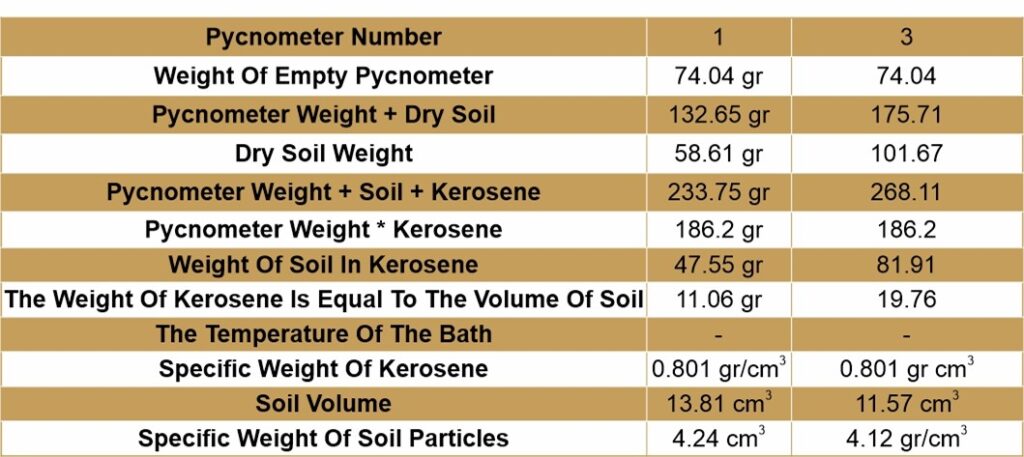

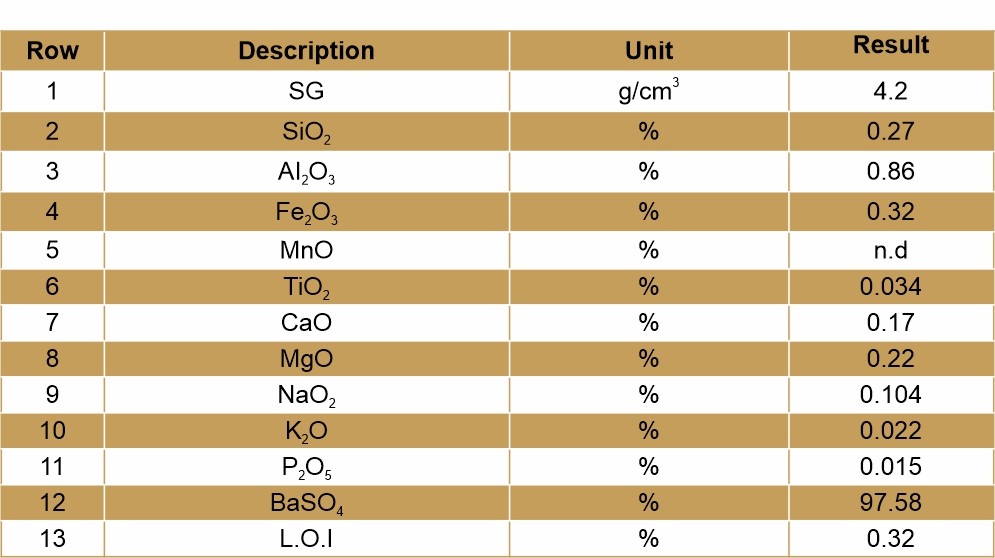

Barite Specifications for Drilling

The barite specifications for drilling are essential to ensure that the barite meets the necessary quality standards for effective use in drilling operations. Vornaco, as a leading manufacturer and distributor of barite, ensures that its products comply with these specifications, including the required specific gravity (between 4.1 and 4.3 g/cm³) and particle size. By adhering to these specifications, Vornaco ensures that its barite is of the highest quality and is suitable for use in various drilling mud applications, ensuring optimal performance in maintaining wellbore stability.

Types of Drilling Mud for Barite Use

There are various types of drilling mud, such as water-based mud, oil-based mud, and synthetic-based mud. Vornaco’s barite is used in all these types of drilling mud to ensure optimal wellbore pressure control. The type of mud selected depends on the specific drilling conditions, such as depth, formation pressure, and environmental considerations. Whether in water-based or oil-based muds, Vornaco’s barite provides the necessary density and viscosity to ensure safe and efficient drilling operations, making it a key component in the drilling fluid formulation.

Drilling Barite for Sale

When searching for drilling barite for sale, Vornaco offers high-quality barite at competitive prices for use in drilling operations worldwide. As a well-established manufacturer and supplier, Vornaco ensures that the drilling barite sold meets the required specifications for pressure control and wellbore stability. The price of drilling barite for sale can vary based on factors like quality and quantity, but Vornaco provides affordable and top-quality products to suit the needs of any drilling project. Customers can rely on Vornaco’s barite for both standard and specialized drilling needs.

read more about uses of red barite on vornaco article.

Barite Drilling Mud Price

The barite drilling mud price depends on several factors, including purity, specific gravity, and location. Vornaco, as a trusted barite supplier and distributor, ensures that its pricing remains competitive while maintaining the high standards of quality that its customers expect. The cost of barite drilling mud is affected by global supply and demand, transportation costs, and regional factors. By sourcing barite from reputable mines and ensuring that it meets international standards, Vornaco provides cost-effective barite without compromising quality.

Barite Drilling Mud Density

Barite drilling mud density plays a crucial role in managing wellbore pressure. Vornaco provides barite with a specific gravity ranging from 4.1 to 4.3 g/cm³, which is ideal for maintaining the required density for pressure control in deep drilling operations. As a leading supplier of barite, Vornaco ensures that the barite drilling mud density is consistent and reliable, optimizing the performance of the drilling fluid. The proper density helps in preventing blowouts and stabilizing the wellbore, ensuring safety and efficiency during drilling.

Drilling Barite is essential for pressure control in drilling fluids. For superior quality kaolin, Vornaco stands out as one of the leading Kaolin Manufacturers, offering premium kaolin products that complement your drilling operations with high performance and reliability.

Drilling Barite Powder

Vornaco, as a leading supplier and distributor of drilling barite powder, offers finely ground barite used in the preparation of drilling mud. The fine powder form of barite ensures optimal mixing and suspension in the drilling fluid, providing the right viscosity and weight to control wellbore pressure. Barite powder is particularly useful in deep drilling operations, where managing pressure at great depths is critical. With Vornaco’s high-quality drilling barite powder, drilling teams can achieve optimal performance in their drilling operations.

Barite in Drilling Mud Applications

Barite is used in various drilling mud applications, primarily as a weighting agent to control pressure. Vornaco’s barite is essential in maintaining the correct weight in the drilling fluid, ensuring wellbore stability and preventing blowouts. As a reputable supplier of barite, Vornaco ensures that its products are suitable for a variety of drilling environments, from oil and gas wells to geothermal drilling operations. The versatility of barite in drilling mud applications makes it an indispensable component for ensuring safety and efficiency during drilling.

Advantages of Barite in Drilling Mud

The advantages of barite in drilling mud are numerous. Barite helps to control the wellbore pressure, which is critical for preventing blowouts and maintaining the stability of the well. Vornaco’s barite also improves the lubricating properties of the drilling fluid, reducing friction and wear on the drill bit. Additionally, barite in drilling mud aids in the efficient removal of rock cuttings from the wellbore, ensuring smooth operations. By using Vornaco’s barite, drilling teams can enhance the overall efficiency and safety of their drilling projects.

Oil Drilling Barite

Oil drilling barite is a specially formulated barite used in oil exploration and extraction. Vornaco, as a prominent manufacturer and distributor of oil drilling barite, provides high-quality barite that meets the demanding specifications for oil drilling operations. Oil drilling barite is essential for maintaining wellbore stability under high-pressure conditions, and Vornaco ensures that its product is suitable for use in both shallow and deep oil wells. By choosing Vornaco’s oil drilling barite, oil companies can ensure optimal performance and safety in their drilling projects.

Barite Powder for Oil Drilling

Barite powder for oil drilling is finely milled barite used in the preparation of drilling fluids specifically for oil exploration. Vornaco’s barite powder for oil drilling is designed to provide the required density and viscosity to control wellbore pressure. The powder form ensures that it mixes easily with other components of the drilling fluid, improving the overall performance of the mud. Vornaco, as a leading barite supplier and producer, guarantees that its barite powder for oil drilling meets the high standards necessary for safe and efficient drilling operations.

Searching for more: Limestone Market

Get in Touch with Us

If you have any questions or need further information about our products and services, don’t hesitate to reach out. Vornaco is here to assist you and ensure that all your inquiries are addressed promptly.

Feel free to contact us via:

- Phone: +98 912 293 9278

- Email: info@vornaco.com

Our team is ready to provide the support you need. We look forward to connecting with you!

Reviews

There are no reviews yet.