Description

Bentonite Clay Drilling Mud

Bentonite clay drilling mud is an essential component in drilling operations, especially in oil, gas, and water well drilling. This mud is composed of a special type of bentonite clay, which is widely recognized for its ability to provide lubrication, control fluid loss, and stabilize the borehole during drilling. The use of bentonite clay in drilling mud ensures that the drilling process is smoother, more efficient, and safer. As one of the leading suppliers of drilling bentonite, Vornaco offers high-quality bentonite clay drilling mud suitable for various applications.

With the right viscosity and swelling properties, bentonite clay can form a gel-like structure that helps to seal the walls of the borehole, preventing the collapse of the well. Its role in maintaining wellbore stability is indispensable, making it a key material in drilling operations worldwide. you can see Where to Buy Bentonite Clay on vornaco.

Drilling Mud Bentonite

Drilling mud bentonite is a specially formulated clay used in drilling fluids to facilitate the drilling process. It is highly effective in preventing the loss of drilling fluid, maintaining the stability of the borehole, and reducing friction during drilling. As a Drilling mud bentonite manufacturer, Vornaco ensures that our Drilling mud bentonite products meet the highest standards of quality and performance.

Drilling mud bentonite is also crucial for cooling and lubricating the drill bit, as well as for cleaning the cuttings from the wellbore. This makes it a versatile material used in a wide range of drilling applications, from oil and gas drilling to geothermal and water well drilling.

Tips for Bentonite Drilling Fluids

- Proper Mixing: Ensure proper mixing of bentonite with water to achieve the desired viscosity. It is important to use the right ratio of water and bentonite to avoid overly thick or thin fluid.

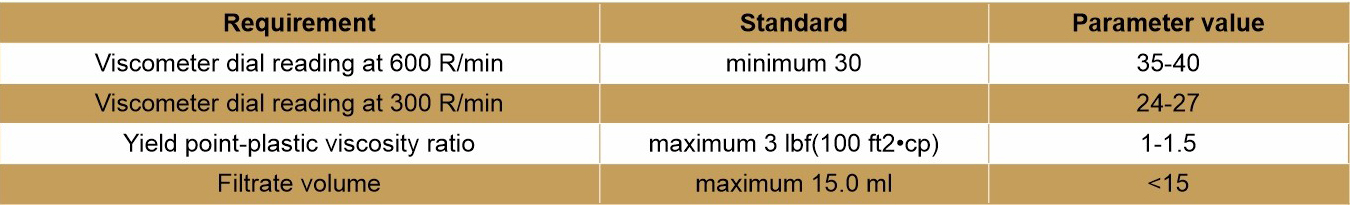

- Monitor Fluid Properties: Regularly check the properties of bentonite drilling fluids, such as viscosity, pH, and gel strength, to ensure optimal performance. Adjustments may be necessary to maintain ideal fluid properties during drilling operations.

- Use Additives: In some cases, additional additives may be needed to enhance the performance of bentonite, such as pH stabilizers, dispersants, or thinners. Always follow recommended guidelines for additive use.

- Disposal Practices: Proper disposal of bentonite drilling fluids is crucial to minimize environmental impact. Follow local regulations and guidelines to ensure safe disposal.

- Temperature and Pressure Considerations: Be mindful of the temperature and pressure conditions in the drilling environment, as they can affect the performance of bentonite-based fluids. Adjust the formulation if needed to maintain stability and fluid loss control.

Advantages of Drilling Bentonite

- Cost-Effective: Bentonite is relatively inexpensive and readily available, making it an affordable option for various drilling operations. Its effectiveness in improving drilling efficiency and safety helps reduce overall costs.

- Improved Drilling Efficiency: Bentonite enhances the efficiency of the drilling process by ensuring that drilling fluid circulates effectively, cutting down on the time required to complete drilling operations.

- Non-Toxic and Environmentally Safe: As a natural material, bentonite is non-toxic and environmentally friendly. It is biodegradable and does not pose significant risks to human health or the environment when used and disposed of properly.

- Versatile: Bentonite’s versatile nature allows it to be used in a variety of drilling applications, from oil exploration to construction, making it a universally applicable material.

- Improved Borehole Stability: By preventing the collapse of the borehole and controlling fluid loss, bentonite ensures that drilling operations continue smoothly and safely.

Uses of Bentonite in Drilling

Bentonite is used in a wide range of drilling applications:

- Oil and Gas Drilling: In the oil and gas industry, bentonite is used as a drilling fluid (drilling mud) that helps to cool and lubricate the drill bit, prevent the collapse of the borehole, and transport cuttings to the surface.

- Water Well Drilling: Bentonite is commonly used in water well drilling to form a barrier that prevents water loss and protects the well from contaminants.

- Geotechnical Drilling: Bentonite is essential in geotechnical drilling operations, such as foundation work and soil testing, to stabilize the borehole and control fluid loss.

- Mining: Bentonite is used in mining operations, particularly in drilling operations for mineral extraction, as it helps prevent borehole collapse and facilitates the removal of debris.

Future of Drilling Bentonite

The future of drilling bentonite is closely linked to advancements in drilling technologies and increased demand for more sustainable drilling practices. As the global demand for oil, gas, and water continues to rise, the role of bentonite in drilling operations will only grow. Researchers are focusing on improving the efficiency of bentonite-based drilling fluids, enhancing their performance while reducing environmental impact.

Furthermore, the development of alternative, environmentally-friendly materials and additives that complement bentonite will likely shape the future of drilling fluids. Innovations in bentonite formulations could make drilling even more efficient and sustainable.

Global Shipping and Export Services for Drilling Bentonite

Vornaco provides global shipping and export services for drilling bentonite, ensuring that our high-quality products reach customers around the world. Our reliable and efficient shipping services ensure timely delivery, making us a trusted partner for businesses in need of drilling bentonite products. With our extensive network and logistics expertise, we can handle large-scale export orders and ensure that your bentonite reaches you on time.

Competitive Pricing for Drilling Bentonite

At Vornaco, we understand that cost is a critical factor when purchasing drilling bentonite. That’s why we offer competitive pricing for our high-quality products, ensuring that you get the best value for your investment. Whether you’re buying in bulk or for smaller projects, our pricing structure is designed to meet your budget while delivering superior performance.

How to Buy Drilling Bentonite from Vornaco

If you’re looking to buy drilling bentonite, the process is simple with Vornaco. Simply contact our sales team to discuss your needs, and we will provide a customized solution that meets your project requirements. We offer flexible payment options, fast shipping, and excellent customer support to ensure that your purchase experience is smooth and hassle-free.

read more : Kaolin Price

Bentonite Powder for Drilling

Bentonite powder for drilling is one of the most widely used drilling fluids due to its exceptional properties. The bentonite powder is highly effective at increasing viscosity, which helps in carrying drill cuttings to the surface, keeping the drill bit cool, and providing lubrication. As a bentonite powder supplier, Vornaco offers premium bentonite powder for drilling applications, ensuring that your drilling operations are both efficient and cost-effective.

Bentonite powder is easy to mix and use, providing consistent results across different drilling projects. Whether you are drilling for oil, gas, or water, our bentonite powder provides the high-quality performance you need for your operations.

Bentonite in Modern Drilling

Bentonite is a naturally occurring clay that plays a crucial role in modern drilling operations, especially in industries like oil and gas drilling, construction, and even in water wells. Known for its unique ability to absorb water and form a gel-like substance, bentonite is widely used as a drilling fluid, also known as drilling mud. This material is essential for improving the efficiency, safety, and environmental sustainability of drilling projects. In this article, we will explore the key properties, environmental impact, uses, and advantages of bentonite in modern drilling operations.

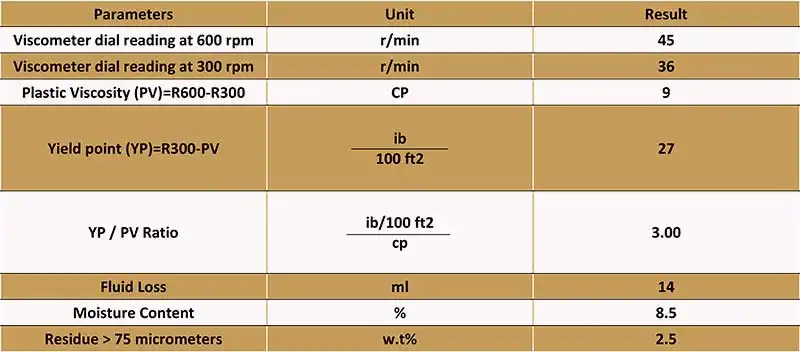

Viscosity and Thixotropy

Bentonite’s ability to increase the viscosity of drilling fluids is one of its most important properties. When mixed with water, it forms a gel-like substance that increases fluid thickness, allowing it to carry cuttings to the surface efficiently. Additionally, bentonite’s thixotropic nature enables it to revert to a more fluid state when disturbed, improving circulation and fluid management.

Environmental Impact of Bentonite in Drilling

Bentonite, as a naturally occurring clay, is often considered an environmentally safe option for drilling operations. When used properly, bentonite helps reduce the environmental footprint of drilling activities by providing an effective solution for controlling fluid loss, reducing the need for more harmful chemicals, and minimizing soil erosion. Furthermore, its non-toxic properties make it a sustainable choice compared to other drilling fluids.

However, improper disposal or overuse of bentonite in sensitive ecosystems can still lead to local environmental issues, such as contamination of groundwater or the disruption of local soil systems. It is essential for drilling operations to follow strict regulations and ensure proper disposal practices to avoid any negative environmental impact.

Introduction to Drilling Bentonite

Drilling bentonite, often referred to as “drilling mud,” is a type of clay that is primarily used as a fluid to aid in the drilling process. It is composed of montmorillonite, a mineral that gives it the unique ability to expand when exposed to water. In the context of drilling, bentonite serves multiple functions including lubrication, cooling, and stabilizing the borehole. Its thick consistency helps to prevent the collapse of the borehole and provides a mechanism for removing drill cuttings from the drilling area.

Bentonite is primarily used in oil and gas drilling, geotechnical drilling, construction projects, and water well drilling. Its versatile properties make it indispensable in drilling operations worldwide.

Bentonite Clay for Well Drilling

When it comes to well drilling, bentonite clay plays a vital role in ensuring the efficiency and safety of the drilling process. The unique properties of bentonite clay allow it to create a stable barrier around the well, preventing fluid loss and reducing the risk of wellbore collapse. As a trusted supplier of bentonite clay for well drilling, Vornaco offers high-quality bentonite clay that helps maintain well integrity and optimize drilling performance.

Our bentonite clay for well drilling is specifically designed to meet the needs of drilling professionals. It provides excellent fluid loss control, borehole stability, and ensures that the drilling operation proceeds smoothly.

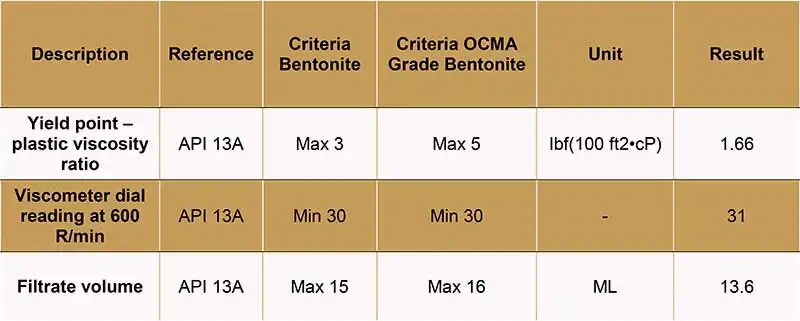

Drilling bentonite is essential in oil and gas exploration, providing viscosity and filtration control in drilling fluids. Its quality and performance are often evaluated based on API standards. Understanding the importance of these standards helps in choosing the right grade. Read our full explanation in: What Is API Bentonite

Bentonite for Drilling Wells

Bentonite for drilling wells is specifically formulated to maintain wellbore stability and control fluid loss during the drilling process. The swelling and water retention properties of bentonite make it ideal for use in drilling fluids, as it creates a stable environment that minimizes the risk of well collapse and reduces friction. As a leading bentonite supplier, Vornaco provides high-quality bentonite for drilling wells, ensuring that your drilling projects are completed safely and efficiently.

Our bentonite for drilling wells offers excellent filtration control, preventing the loss of drilling fluids and ensuring that the well is drilled correctly and safely.

Bentonite in Well Drilling

The importance of bentonite in well drilling cannot be overstated. Bentonite helps to ensure the smooth operation of the drilling process by improving hole cleaning, providing lubrication to the drill bit, and preventing the loss of fluids. It also helps to stabilize the wellbore and prevent the collapse of the well during drilling operations. As an experienced drilling bentonite distributor, Vornaco offers a wide range of bentonite products for well drilling applications.

Our high-quality bentonite ensures that the drilling operation runs smoothly, reducing downtime and improving the overall efficiency of your project.

Well Drilling Bentonite

Well drilling bentonite is specially formulated for use in water well drilling, geothermal drilling, and oil and gas exploration. The unique properties of bentonite make it an essential material in the drilling process, offering excellent support in stabilizing the well and ensuring fluid loss control. As a trusted bentonite manufacturer, Vornaco provides premium well drilling bentonite to meet the specific needs of drilling contractors worldwide.

Our well drilling bentonite helps maintain proper wellbore stability and prevent fluid losses, ensuring that your drilling projects are completed without complications.

Bentonite Drilling Mud for Sale

Vornaco offers premium bentonite drilling mud for sale to meet the needs of drilling professionals around the world. Our bentonite drilling mud is specially formulated to provide superior performance in drilling operations, ensuring fluid loss control, borehole stability, and efficient wellbore cleaning. We offer our bentonite drilling mud in bulk and in customized quantities to suit the needs of your project.

Explore our range of bentonite drilling mud for sale and find the right product for your drilling operation.

Bentonite Drilling Mud Price

The bentonite drilling mud price can vary depending on factors such as the grade of bentonite, the quantity required, and market conditions. At Vornaco, we offer competitive pricing for bentonite drilling mud, ensuring that our clients receive the best value for their investment. Our bentonite drilling mud is designed to meet international quality standards, offering superior performance and cost-effectiveness.

If you’re looking for affordable bentonite drilling mud, Vornaco provides high-quality products at prices that fit your budget.

read more : Bitumen Price

Get in touch with us through:

Phone number: +98 912 293 9278

Email: info@vornaco.com

Why Choose Vornaco for Your Drilling Bentonite Needs

Vornaco is a trusted drilling bentonite manufacturer, supplier, and exporter known for providing high-quality bentonite products at competitive prices. With years of experience in the industry, we are committed to providing the best drilling bentonite solutions to our clients. Our superior products, exceptional customer service, and reliable delivery make us the preferred choice for businesses worldwide.

Reviews

There are no reviews yet.