Silica Glass

Silica glass, also known as fused silica, is a type of glass made from silicon dioxide (SiO2), the same substance that makes up sand. Unlike traditional glass, which is made by melting various minerals together, silica glass is created by melting pure silica in a controlled environment. This unique composition provides silica glass with exceptional properties, making it a highly versatile material in many industries, including electronics, optics, and manufacturing.

In this article, we will explore what silica glass is, its properties, various applications, and the manufacturing process behind it. Additionally, we will compare it with other types of glass and highlight the advantages and challenges it presents. By the end, you’ll have a comprehensive understanding of silica glass and its crucial role in modern technology.

Silica glass is an essential material used in the production of high-quality glass and advanced technologies. If you’re interested in learning about the cost factors associated with silica and how it impacts the production of glass products, you can explore the latest trends and pricing details on Silica Cost. Stay informed about the market to make better purchasing decisions!

What is Silica Glass?

Silica glass is a non-crystalline material that is made entirely of silicon dioxide. Unlike ordinary glass, which contains a mix of soda, lime, and other ingredients, silica glass is formed by melting high-purity silica sand. This results in a transparent, solid substance that is highly durable and resistant to various environmental factors.

This material is prized for its purity and ability to withstand extreme conditions. Because it lacks crystalline structure, it exhibits unique optical and thermal properties that make it suitable for high-performance applications. Silica glass is often used in the production of optical fibers, lenses, and various laboratory equipment.

Properties of Silica Glass

Silica glass has a wide range of properties that make it unique among other glass materials. One of its most important characteristics is its high melting point, which exceeds 1,700°C (3,092°F), making it highly resistant to thermal shock. This means that silica glass can withstand rapid temperature changes without cracking or breaking, a property that is vital for high-temperature applications.

Additionally, silica glass exhibits excellent optical transparency, especially in the ultraviolet (UV) spectrum, making it ideal for optical and laser applications. It is also chemically inert, which means it does not easily react with other substances, even in harsh environments. These properties contribute to the wide use of silica glass in industries such as telecommunications, aerospace, and electronics.

Applications of Silica Glass

Silica glass is used in a variety of industries due to its outstanding properties. In telecommunications, silica glass is used to make optical fibers, which are essential for high-speed internet and communication networks. The glass’s optical clarity and minimal signal loss make it the preferred material for fiber optic cables.

In the aerospace and defense sectors, silica glass is used in the manufacture of windows for high-performance aircraft, satellites, and spacecraft. Its ability to withstand extreme temperatures and its optical properties are critical for ensuring the safety and efficiency of these technologies.

Other industries that rely on silica glass include electronics (for semiconductor components), medical devices (such as surgical tools and equipment), and manufacturing (in high-temperature furnaces and reactors).

Types of Silica Glass

There are several types of silica glass, each suited to different applications. The most common type is fused silica, which is produced by melting high-purity silica in an electric furnace. This form of silica glass is typically used in applications requiring high thermal resistance, such as in semiconductor manufacturing or high-temperature laboratory work.

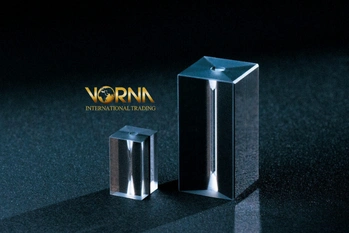

Another type is quartz glass, which is made from natural quartz crystals. Quartz glass is often used in the production of high-performance lenses and optical devices due to its superior optical properties.

Lastly, synthetic silica glass is made by chemically vaporizing silicon tetrachloride and then condensing it into a solid form. This type of glass is known for its extreme purity and is commonly used in the production of optical fibers and advanced optics.

Silica Glass vs. Other Types of Glass

When compared to other types of glass, silica glass stands out due to its superior thermal and chemical resistance. Unlike soda-lime glass, which is commonly used in everyday products like windows and bottles, silica glass can withstand much higher temperatures and is chemically inert.

Another important distinction is its optical properties. While regular glass has limited optical clarity, silica glass offers excellent transparency across a wide range of wavelengths, including UV light. This makes it essential for use in optical fibers, lenses, and other specialized equipment.

In terms of mechanical strength, silica glass is not as strong as tempered glass or borosilicate glass, which are used for applications requiring high impact resistance. However, silica glass excels in thermal and optical performance, which makes it irreplaceable in many high-tech industries.

Manufacturing Process of Silica Glass

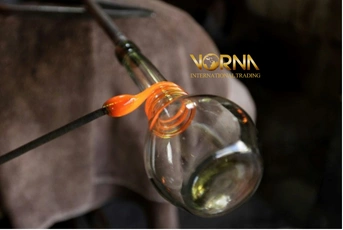

The manufacturing process of silica glass involves the melting of high-purity silica sand or silicon dioxide at extremely high temperatures. This process is typically done in a furnace that reaches temperatures upwards of 1,700°C. Once melted, the silica is formed into various shapes, including sheets, rods, or tubes, depending on the desired end product.

The purity of the silica used in the production of silica glass is crucial. Any contaminants can affect the optical properties and overall performance of the material. In some cases, additional steps such as polishing and annealing are performed to further improve the surface quality and remove any internal stresses.

After the initial production, silica glass can undergo further processing to create specific products, such as optical lenses, fibers, or semiconductor wafers. The versatility of silica glass allows it to be molded and shaped into a variety of forms to suit different applications.

Advantages of Silica Glass

The primary advantage of silica glass is its ability to withstand high temperatures. This property makes it essential in industries that operate under extreme conditions, such as the aerospace and semiconductor sectors. Additionally, its high optical clarity and resistance to UV light make it ideal for use in optical fibers and lenses.

Another key benefit is its chemical inertness. Silica glass does not react with most chemicals, which allows it to be used in harsh environments without degrading. This feature is particularly important in industries like pharmaceuticals and chemical processing, where glass containers or equipment need to remain intact in the presence of corrosive substances.

The high strength-to-weight ratio of silica glass also makes it a popular choice for lightweight applications, such as in aerospace components.

Challenges and Limitations of Silica Glass

Despite its many advantages, silica glass does have some limitations. One major drawback is its brittleness. While silica glass is resistant to thermal shock and high temperatures, it is more prone to breaking or cracking upon impact compared to other types of glass, such as tempered or laminated glass.

Additionally, the manufacturing process of silica glass can be costly and energy-intensive. The need for high temperatures and specialized equipment to produce the material contributes to its higher cost compared to conventional glass.

Finally, silica glass can be difficult to process into intricate shapes due to its brittleness, which can limit its use in certain applications.

Future Trends and Innovations in Silica Glass

The future of silica glass looks promising, with ongoing research focused on improving its properties and expanding its applications. One area of development is the creation of more robust, impact-resistant forms of silica glass, which could address its current limitations in terms of mechanical strength.

Another exciting development is the use of silica glass in next-generation technologies such as quantum computing and advanced photonics. Researchers are exploring ways to leverage the unique optical properties of silica glass to create more efficient and powerful components for these emerging fields.

As industries continue to demand higher-performance materials, silica glass will likely play an even more important role in shaping the future of technology.

While silica glass is an important material in the glass and tech industries, understanding the broader properties of silica itself is crucial. To dive deeper into what silica is, its various forms, and how it’s used in multiple sectors, check out our article on What Is Silica for more detailed insights.